Little Known Questions About Motorcycle Parts New Zealand Specialists.

Table of ContentsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingMotorcycle Parts New Zealand Specialists - TruthsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe 7-Second Trick For Motorcycle Parts New Zealand SpecialistsThe 8-Minute Rule for Motorcycle Parts New Zealand Specialists7 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe 10-Minute Rule for Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand Specialists

So, connect to one of our specialists today.CNC machining innovation is swiftly becoming the prime focus of various manufacturing procedures around the globe as a straight outcome of its numerous advantages over other techniques. Additionally, the markets that make motorbikes have jumped on board with this fad. One of the most innovative firms are now developing their engine parts and wheels using machining methods originally created for motorbike components.

On the other hand, the effects of industry are the main focus of this write-up. Let's get right into it. You might be asking yourself why we use. It is not difficult to fathom the elements that brought about this result. Since we have your interest let us explain the reasoning behind this modern-day development in the motorcycle production industry.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

In addition, you have complete control over the look of the components, even down to the minute information. Sometimes, motorcyclists may decide to spruce up their experience by installing aftermarket parts or modifying the bike's makeover.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Described

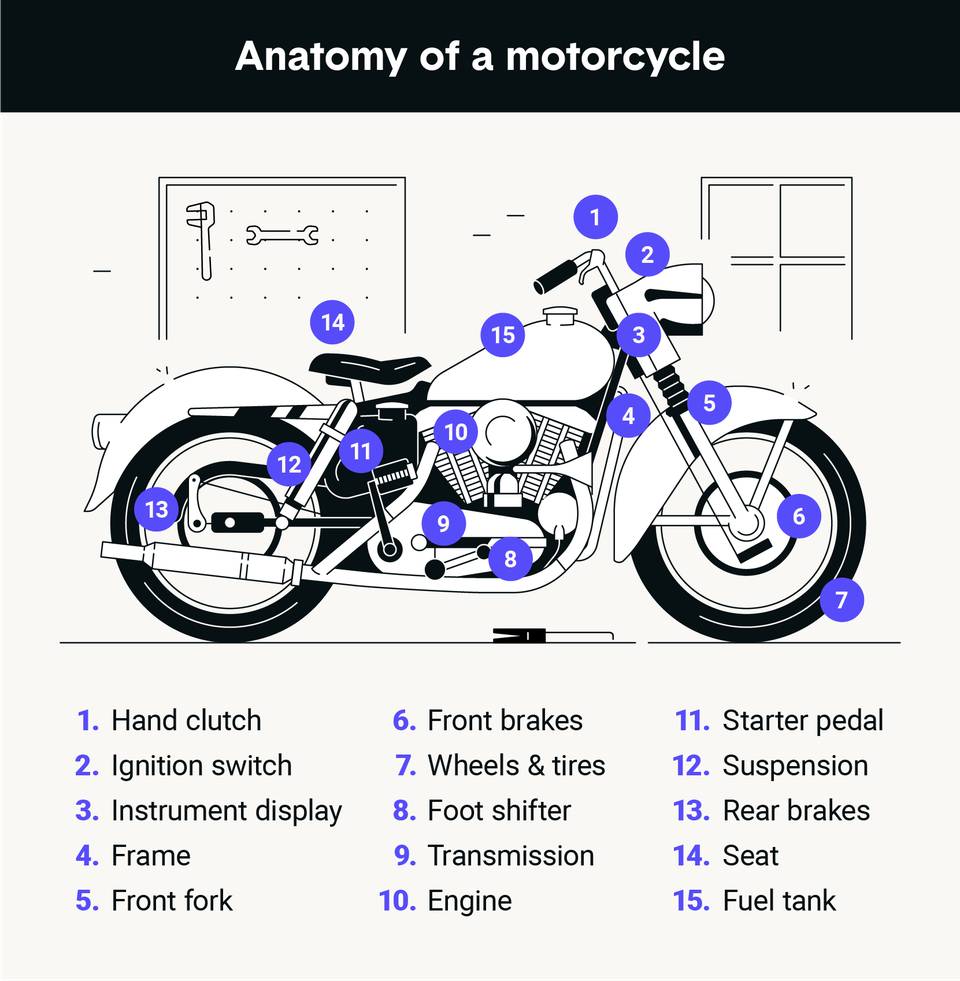

CNC machining may be used to make almost all of a motorbike's steel and plastic components. To continue, we'll review a number of machined components for motorcycles.

Milling treatments are utilized to obtain the desired degree of wheel modification. An additional aspect of the motorbike that may be customized is the tires.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

When it comes to a vehicle (or a motorbike), one of the most essential component is the engine. A number of people mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and call for designs with a high level of accuracy.

Use only top quality items, nevertheless, given that these lights are crucial for the security of motorcyclists and other motorists or individuals on the roadway, specifically at evening. Motorcycle fronts lights have 3 main parts: the light bulb, or light resource, the lens, learn the facts here now and the housing.

Milling procedures with a perfect coating would lead to the lenses having a reflective high quality that is similar to that of a mirror. The cover, on the other hand, is not composed of vulnerable materials; rather, it is created out of tough polymers that can be machined right into more elaborate patterns.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

They often have sophisticated geometries with a riches of minute details. Motorcycle manufacturers often cast these components, but just for the production of bespoke components. Nonetheless, CNC machining is the method of selection when creating distinct pieces. Machining on 5 axes in today's world is the means through which any type of style shape may be understood.

The success of the process is contingent on the mill cutters' capacity to additional hints compute subtle and challenging angles properly. Pick Runsom for your tailored motorcycle components! We have the capacity to make difficult and fashionable components making your bike unparalleled. The majority of are crafted from light weight aluminum or steel alloys, each of which has its usages and advantages.

Here are a few instances of steels often used in motorcycle part machining. Light weight aluminum is the key material used by firms specializing in creating custom motorcycle parts to develop most of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional metal that is very light in weight and has terrific machining top qualities because of its high mechanical strength. This material may be created right into almost any type of shape and maintains its dimensions well. Also mission-critical elements that need a high level of precision may take advantage of their usage.

More About Motorcycle Parts New Zealand Specialists

One more metal that sees heavy use in the production of CNC-customized elements is magnesium. It is among the lightest steels that are currently accessible and has superb machinability attributes and toughness appropriate with its reduced weight. Among the downsides of magnesium is that its dirt may conveniently catch fire.

Their most common usage in creating various bike parts is bolts, such as screws and bolts. Their low sensitivity to oxidation and deterioration makes them perfect for this use.

Unknown Facts About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and milling are the fundamental processes. Alternative methods exist, such as boring. Let's check out many of these machining methods detailed. The CNC transforming strategy is taken into consideration a subtractive production method. Additionally, it needs maintaining bars of material, frequently plastic or metal, in setting and after that turning a reducing tool to get rid of sections of the material as the product is turned.

These techniques are similarly crucial and produce parts with high accuracy and regular quality. The processes assist boost the total top quality of the machined motorbike parts.

The Only Guide for Motorcycle Parts New Zealand Specialists